WHY 2 COMPRESSION STAGES ARE NECESSARY TO BE INCORPORATED WITHIN OUR NEWLY BUILT HIGH SPEED FULL-SERVO PACKAGING MACHINE?

WHY 2 COMPRESSION STAGES ARE NECESSARY TO BE INCORPORATED WITHIN OUR NEWLY BUILT HIGH SPEED FULL-SERVO PACKAGING MACHINE?

Have you ever experienced any painstaking technical issues of the stacked diapers compression process before being packed and sealed?

One of the major problems of stack compression is where the diaper pieces will squeeze and pop out from the stack and deformation occur that totally ruins the products before reaching the market. This is the result due to direct full compression where the (diaper) pieces have insufficient time and space to keep the alignment organized.

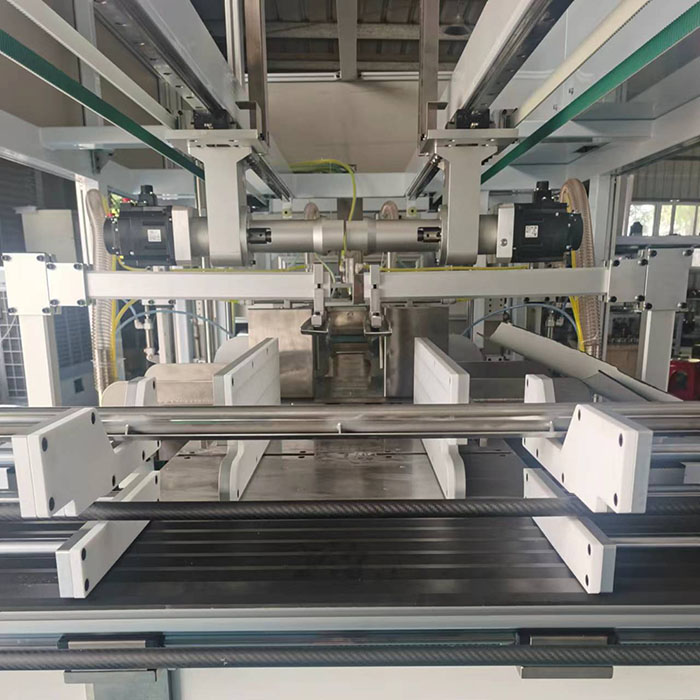

To tackle this such a possible issue during the packing process, the dual compression stages have been invented and incorporated within our latest Fully Automatic Packaging Machines (with auto.size-changing function) by first gently and partially compressing the stacked (diaper) pieces and then fully compressing the whole stack subsequently on the second stage. Hence the gradual speed of compression will be generated and permitting more time for the stacked pieces to keep the alignment and arrangement neat, organized and uniformedOur recent order of this latest machine from South-East Asian & African countries such as Indonesia & Ghana and have receive positive feedbacks from our clients.

![]()

![]()

For further enquiries and ordering details on our latest Fully Automatic Diaper Packing Machine with Auto. Size-changing functions, please feel free to contact us through Whatsapp or email as shown:

WhatsApp: +852 94139911

H/P:+86 184 20690874 /+86 592 5668012

IG: xiamenbroad

Facebook: @xmbroad